Not needing food or shelter anymore because you’re dead is also great for your budget.

Going out with a bang is great for everybody’s budget!

Probably until you get to the megaton range. At that point I suspect you’re probably bringing a lot of people with you.

Na, it sounds good but your ungrateful relatives take all your money.

Wont even take off

This is called the Jesus nut. It holds the main rotor onto the helicopter. It doesn’t have any redundancy, so if it fails, you’re going to be meeting Jesus in moments.

Thankfully this one is built of many redundant layers instead of just one layer of metal.

TIL there’s many Jesus’s nuts are all over the sky.

Chem trails! Jaysus is nutting!

To be fair, if you don’t have the files. This is an easy way to make a prototype and fit it, and then if it fits you can order it in metal. This is a cheaper proces in iternating in metal from the start

If the choice is between being out $1,590 or plummeting to my death in order to save a few hundred bucks, then I’ll just pay the $1,590.

They call it the Jesus Nut for a reason.

Because it makes Jesus Nut?

Because if it fails, only Jesus can save you

Bull honkey, knock the rust off 'er, slap on some grease and she’s good as new

Got that Alaskan Airframe and Powerplant license, I see.

I reckon that’s right pardner

Spoken like a true Boeing engineer.

That’s what has me grinning! I’m not replacing a Jesus nut with anything that didn’t come straight from the manufacturer.

I’ve actually flown Robinson helicopters, and there’s no nut that looks like this on the helicopter.

So, probably a joke.

Yeah you just have to deal with mast bumping, as if thats any less worrying.

Mast bumping is such a gentle term for the main rotor just fucking off and the helicopter going from an aircraft to a falling object.

You’ve flown Robinson?

Willingly?

And lived? Brave soul.

Good news is, that part ain’t getting off the ground. Bad news is, the rotor might get kinda fast first

No. No.

For this part? No. You want the real deal. The proper metal. The proper alloy, annealed correctly.

Yeah, but to get there, you need a prototype. There’s nothing wrong with testing the fit using 3D printing before you order a copy in real materials, just don’t put it under any load.

You could print it with normal plastic filaments, but those can deform and screw with the measurements if you’ve got a really tight fit, so metal printing is a good use there.

I get what you’re saying but this is what is called the “Jesus Nut”. That’s because it’s one piece that essentially holds your entire helicopter up. To quote the Wikipedia page: …“whose breakdown would result in catastrophic consequences, the suggestion being that in such case the only thing left to do would be to pray to Jesus, or that the component’s importance could be likened to the importance of Jesus to Christianity.”

You don’t prototype this. You don’t make these. You get the tested, real part. There is no scenario in which making your own is advisable. Unless you’re an engineer for an aircraft manufacturer who is going to be doing rigorous testing then you should just buy the part ready made and certified.

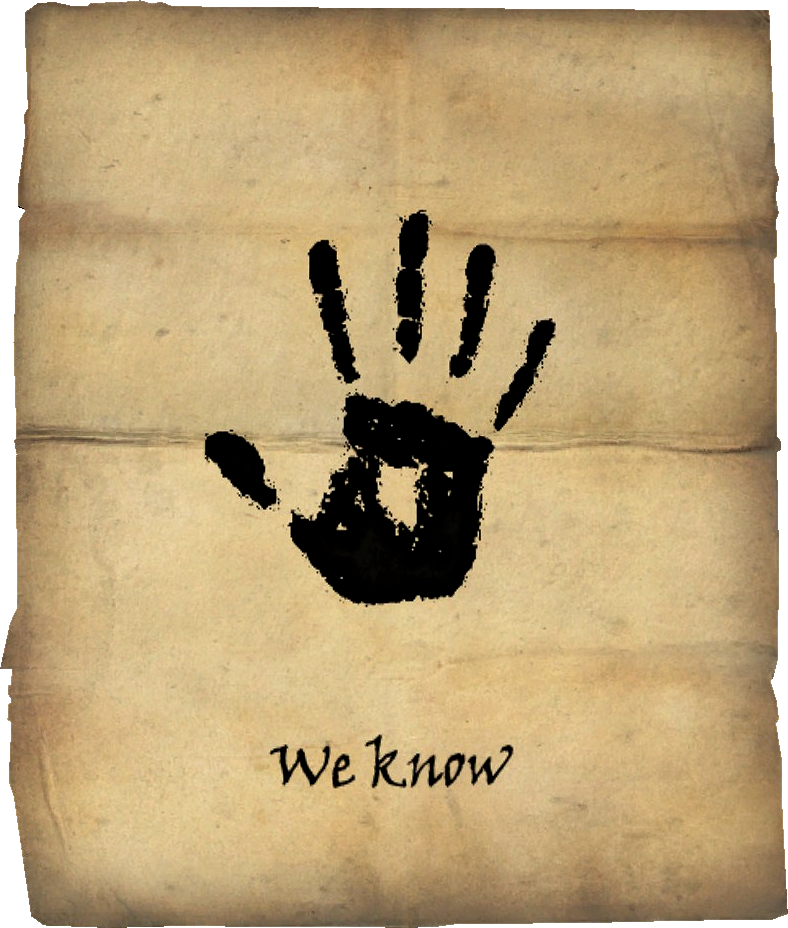

Lol the meme is the picture on the wiki mirrored and edited

no scenario

Absolutes always get me scheming. What if you’re stuck on a deserted island with only a working 3d printer and a helicopter missing this part? What then? Yeah probably swim.

Use the radio in the helicopter to call for help?

Gilligan already broke it.

I’d say cry, the small loss of water will bring the sweet release of death one step closer.

You build a boat out of the helicopter and 3d printed parts. I’ll be a bad boat, but the best case scenario for this 3d printed part is that it breaks under static load

Hah, Jesus nut

So the design has never changed since it was made? The engineers have never needed to figure out an upgrade or slightly different way of doing it?

Of course randos don’t make them in their garage, but somebody does make them, and I don’t see a problem with experts incorporating this into their workflow. I don’t know why you do?

I think we’ve lost the context here. The person in the photo self-describes as a consumer - they should not be making this. That’s the joke.

Somebody who would be prototyping something like this works for an aircraft manufacturer, and there’s probably less than a thousand of such people in the world. If you are one such person you know so.

I’m one of those people and there’s absolutely no way I could produce a safe copy of this for less than $1590.

The part already exists though?

You can also print in different metals with various processes like laser sintering, still though, there are some things you might not want to skimp on: Probably best to stick to approved parts.

It wouldn’t surprise me if such a critical part was cast as a single metal crystal. The stresses on that rotor mist be unbelievable.

Pretty sure you don’t want a be doing that with an aircraft.

I’m sure it’s safe if you can do it correctly, but I would not trust myself like that

I printed an ABS powerwheels gear out for a friend to test the fit. 100% infill, tt was chonky, was going to get it redone in nylon.

it fit and was ripped to shreds in 30 seconds :)

Try 200% infill next time

Have you seen the prices on the non-Euclidean filament these days? Only Voidstar labs can afford that shit.

FYI: Plastic Welding is a thing that exists. Use it literally all the time to fix what my kids break.

Power Wheel Wheel included. Takes literally seconds to fix a crack

Gear D was what broke, it delivers the full thrust to the final axel and take most of the force when the wheel take a hit. there’s no welding that

Someone who owns a helicopter but is bitching about spending $1500???

People think private pilots are rich because airplanes are expensive. They’re not - they might be upper-middle class (with a mortgage and other debt) but most have to budget their aviation spending. Truly wealthy people don’t fly their own planes, they hire pilots and crew, and probably have no idea what a Jesus nut looks like.

That said, this is obviously satire/bait.

I had to check up Jesus nut, and learned that’s what it’s called because it’s the one you pray will hold because if it don’t you crash. Hahaha

I know the post is a joke but it’s more like “somebody owns a helicopter rental business and they’re bitching about repairs on helicopters they themselves don’t pilot so they themselves aren’t in danger”

Helicopter landlord!

land?.. Helilord.

Oh, this perspective didn’t occur to me, it makes everything so much worse 😅

How do you think they managed to own a helicopter?

Unfair. I’ve spent my entire life not buying expensive (or even cheap) helicopter parts and I still don’t have a helicopter.

I do have a 3d printer, though…

Hm…

Jarvis! Preheat the print bed.

And now you’ve just given Boeing executives some great ideas how to further reduce costs! I don’t thank you!!

I have news for you:

3D printing is very common in the aviation industry by now.

They don’t exactly use TPU and Bambulab printers, though… ;-)Oh yes they do.

Aircraft crashed in Gloucestershire after 3D-printed part collapsed - BBC News https://share.google/v8NcjqE0tAK34AiI7

IIRC that entire plane was a DIY plane from a popular kit, not a commercial vehicle.

(not clicking on a Google shortlink)

TPU? You’ll get PLA and like it

“Hey, John! How much are we paying those 3D printers again? I found one here that looks like it would do just the same job for much less!” – quote that will show up in a leak in 2032 after a handful of planes crashes.

ChatGPT said it would work.

Big Helicopter hates this one weird trick:

And so do the people inside the big helicopter!

And those within range of its flying blades

3d print part, with added shrinkage factor Finish 3d printed part. Cast the print in cement. Burn the plastic out the new mold. Fill mold with the alloy of your choice. Pre-finish, finish metal part. Congrats, many 1000s spent on furnace materials for a 1.5k part but a new understanding for lost wax casting.

3d printing is the king of prototyping. Just print the part with sprues and all. Do a one off, write SOPs, prepare for full production. Profit.

Discover that 3d printing can’t meet the precision requirements and cast metal won’t meet the mechnaical requirements, gear shears, make peace with your fate, fall from sky onto local orphanage’s annual puppy adoption drive.

Those orphans aren’t orphans any more… Progress.

Real talk I cast turbine blades for IGT and Aerospace (not an engineer, just a floor worker). It was my impression that inside those turbines is an incredibly hostile environment (hot, acidic, g-forces), and still we cast them. We did some single crystal stuff for the really demanding parts. Is cast metal really that flawed?

Out of all of the things that you would want to be comfortable with taking risks on, the Jesus Nut on a helicopter is not one of them.

There are no fallbacks if that fails.

The only thing that can save you is a miracle from our Lord and Savior, Jesus Christ, if the Jesus Nut fails on your helicopter while you’re in air.

No, but metallurgy isn’t a straightforward peocess like they were kinda implying. Gears, especially extremely high performance ones like in aerospace, have partial hardening, surface treatments, even exotic things like mixed alloys to ensure they meet the mechanical demands required of them. You can’t simply cast a gear and expect it to work - in this case if you tried as they were describing you’d likely just have the teeth shear when you tried to take off and you’d be fine, but there’s a real good reason that part costs as much as it does and it’s not just the administrative costs that come with aviation part documentation requirements.

Casting itself is fine for many applications, and advanced casting techniques are incredibly complicated and suitable in one form or another for many applications, but not all things should be cast.

It was me kinda implying it. Just making a shit posting comment in a shit post community.

Oh lol, mixed up you and bizarroland.

Is fine. Didn’t think I’d TIL on a shitpost comm, but you sent me down a wikihole. Always fun

Oh, I love how rabbit-holey metallurgy can get. One of my favorite topics is the processes used to cool hardened gears that have to be ground. Keeping the temperatures below a certain point so that they don’t lose the temper is surprisingly difficult even with external flood cooling (or working fully submerged), so you wind up with insane looking profile cutters that have cooling lines built into them directly.

Also the techiques to monitor the diameter of abrasive grinding tools get wild, like monitoring the capillary pressure of the coolant spray and similarly insane feats of precision.

In some past aerospace work, I’ve seen requirements where, if you do use cast parts, you have to cast extra parts on each lot to use for destructive testing. Specifically to inspect the cross sections for flows or grains or whatever they want to look at.

Back maybe 25 years ago I got to tour inside Howmet in Whitehall, MI as part of a class. They did casting of turbine vanes for jet engines. Damned impressive process, and thorough quality checks x-raying every one for flaws. Finding out that each vane has coolant channels cast in was interesting, and a bit unnerving, since they get operated at temperatures above the melting point of the metal! I always think about that when I get on a plane.

Dead orphans are still orphans.

Just get one of those million dollar printers

Dissect a mosquito and use its proboscis

LOL

Discover that 3d printing can’t meet the precision requirements and cast metal won’t meet the mechnaical requirements, gear shears, make peace with your fate, fall from sky onto local orphanage’s annual puppy adoption drive.

Bold assumption to make that a home-jobber would get you up into the sky.

I bet that if you were dedicated enough, you could probably make a home helicopter.

Whether you could survive the first or the tenth flight, that’s a different story, but I bet you could get into the air with something that was homemade.

Yeah, there’s tons of plans out there for DIY helicopters you can get from the hobby aviation community. Usually the sticking point is making the rotor blades themselves, but I’ve seen some people get off the ground with carbon-fibre laminate blades. Not sure I’d trust them personally but it does work.

More interesting than working until I have a heart attack

Cement? They make sand specific for casting. Generally you don’t want to play with heating cement, right?

EDIT: Oh you mean dry cement?

Industrial high precision lost-wax usually has a mold made from many layers, often either done in traditional monlith casting frames (big slabs of cement or plaster or casting sand or etc) or formed by dipping the parts into various cement slurries (a bit like a candle. The first few layers are generally a low-additive “print coat” made from ceramics akin to porcelain (that won’t react with the material being cast), and then for strength they’re bulked up with thick layers of stuff that usually has been bulked up with sand and recycled shells of precious castings that have been crushed down.)

It’s a fascinating process.

I’m not sure I’ve ever fallen more in love with a process than lost wax casting and its foam cousin, from the moment a tutor showed me a polystyrene cylinder head I was hooked lol. I’ll get a setup going some day.

Just a Lemmy shitpost comment, don’t think about it too hard Sure fine sand and a runny plaster, ceramic capture detail. But you still bulk it out with rougher stuff to give the mold heft.

Maybe not cement. But I also wouldn’t recommend doing back yard casting for Life critical parts if you’re asking what your detail capturing materials should be and what your bulking out materials should be.

There are Casting Wax Filaments, btw. You don’t need to use plastic if you’re going to burn it out.

No notes, that’s awesome!!!

I have zero intention of getting into 3d printing or back yard casting. But it’s cool that intersection has products.

Wasn’t there a news story recently where someone had actually done this and (obviously) died?

Yeah, this is the before photo.

I think it was an airplane air inlet duct that melted and collapsed. And it was bought from a 3D printing supplier, not printed themselves. The person aboard lived. So it was more subtle, which makes it even more insidious. I.e. even for a simple plastic tube you need the expensive part, for non-obvious reasons.

RIP

AND TEAR

UNTIL IT IS DONE

You are ready to own an airplane if you can wake up in the morning, burn a $100 bill and flush it down the toilet without feeling anything.

You are ready to own a helicopter when you can do the same thing, except with ten $100 bills.

With a helicopter, I think you also need to be actively suicidal.

Not my video, but I did ride it that year at the World Freefall Convention.

One time, this was back in my skydiving days so a very long time ago, the drop zone’s CASA 212 was down due to a bad hydraulic pump. The pump finally arrived and the DZO asked me to help him install it. He was a certified A&P, I just had a lot of experience wrenching on cars but it allowed me to get a lot of free jumps due to helping him out on things like this.

He handed me the pump, which was a LOT lighter than I expected and told me with a smile: “Don’t drop it.”

In inquired as to how much it cost and he replied: “$10,000.”

I was holding a pump in my hands that weighed barely 10 pounds that cost more than my car (this was circa 1998 or so).

A couple years later the igniter box on the port engine died and I helped him replace it… That was a cool $15000. The engines were about $250,000 a piece back in those days.

With all the bad shit happening due to corrupt government agencies, it’s refreshing to read comments in this post about how the FAA is still anal as fuck like they should be, though flying on a Boeing still makes me nervous.

I honestly don’t even believe that bolt is that cheap. I read horror stories about a set of 4 normal ass “aviation grade” screws that cost thousands of dollars.

Its the signatures that validate the screws that you’re actually paying for.

Is that why those two helicopters crashed into each other in New Jersey?

Not likely, this would get ripped apart on engine start.

For a crash, you need to at least get to the part where you attempt a takeoff.

It’s a Robinson. It crashed as soon as you thought about flying it.

Ok, i’ll bite: 3D print… in what material?

it’s a joke. Morons are crashing planes with 3D printed parts made with plastics designed for Pikachu figurines.

If it only cost pennies to print it’s not strong enough.

Yeah but it’s some serious costs savings!

“Don’t have to pay pilots if they’re dead” – some CEO, probably

PET, of course!

So is the bolt food safe?

It’s PET, so probably.

Tpu